Discover the intricacies of Ksb Wk systems in this extensive guide. Ksb Wk systems, known for their advanced engineering and efficiency, are essential in various industries. From their pivotal role in fluid dynamics to their state-of-the-art technology, Ksb Wk systems exemplify modern industrial progress. Their application across sectors demonstrates both their versatility and reliability.

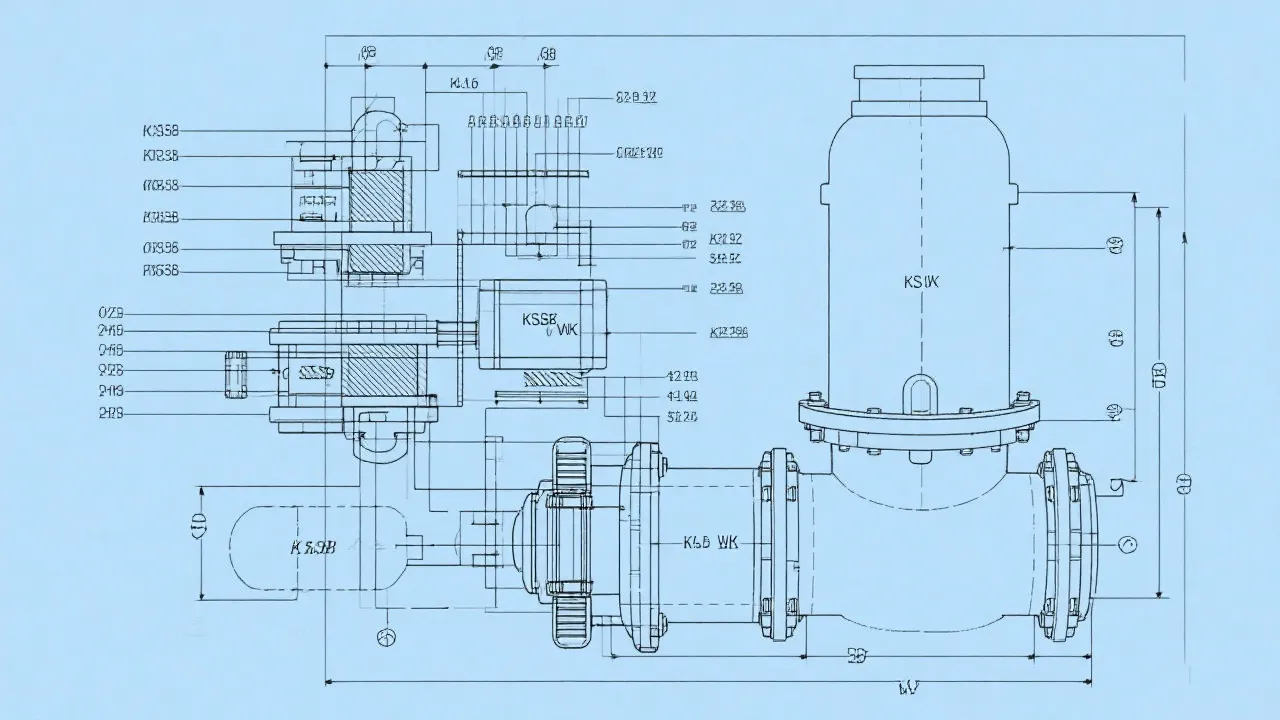

Ksb Wk systems are integral components in the field of fluid dynamics, known for their high efficiency and robust engineering. These systems are utilized across numerous industries, ranging from manufacturing processes to energy generation, due to their ability to handle complex fluid operations with precision and reliability. By comprehending their functionality and application, professionals can implement them effectively to achieve their operational goals.

The primary advantage of Ksb Wk systems lies in their innovative design, which incorporates cutting-edge technology to optimize performance. These systems are engineered to manage high-pressure and high-temperature fluids while maintaining energy efficiency, which is crucial in minimizing operational costs and environmental impact. This technology includes advanced materials that exhibit strength and resistance to corrosion, making them suitable for diverse environments where conventional materials may fail.

Furthermore, Ksb Wk systems take advantage of smart technologies, including automated controls that monitor and adjust system parameters in real-time. This feature allows for immediate responses to changing conditions in a fluid's properties, such as viscosity or flow rate, enabling operators to make informed decisions while reducing the risk of failure.

Ksb Wk systems find applications across a variety of sectors, including chemical processing, water treatment, oil and gas, and energy production. By facilitating the seamless movement and control of fluids, they help to streamline operations and ensure quality production outcomes. For instance, in the chemical processing industry, these systems handle hazardous materials efficiently while ensuring operator safety and compliance with environmental regulations.

In the water treatment sector, Ksb Wk systems play a pivotal role in managing water distribution and treatment processes. Their reliability ensures a consistent supply of clean water, which is crucial in both residential and industrial applications. In the oil and gas industry, they are employed in drilling, refining, and transporting materials, where their ability to perform under extreme conditions is invaluable.

Moreover, in the energy production sector, Ksb Wk systems contribute to enhanced efficiency in cooling systems and heating processes. Their design minimizes energy losses, further supporting sustainable energy practices. Thus, the versatility of Ksb Wk systems across different industries not only highlights their engineering finesse but also reinforces their importance in a wide range of applications.

Compared to traditional systems, Ksb Wk systems offer superior durability and resistance to wear and tear. This longevity reduces the need for frequent maintenance, ensuring continuity and stability within operational workflows. In addition, their modular design allows for easy integration with existing infrastructure, enhancing their flexibility and adaptability in diverse settings. The systems are capable of connecting with legacy systems, allowing businesses to update their operations without incurring substantial installation costs.

Additionally, Ksb Wk systems support high levels of customization. Engineers can tailor these systems to meet specific operational demands, whether it be in terms of size, complexity, or the specific characteristics of the fluids being handled. This flexibility means that they can easily evolve alongside advancements in technology or shifts in production demands, ensuring long-term viability.

Ksb Wk systems are designed to meet rigorous industry standards for safety and performance. Each unit is subjected to extensive testing to ensure compliance with international regulations, making them a reliable choice for critical applications. The systems adhere to standards set forth by organizations such as ISO, ASME, and API, ensuring they can perform under the demanding conditions typically encountered in industrial environments.

These specifications often include parameters like pressure ratings, temperature limits, and compatibility with various fluid types. Moreover, Ksb Wk systems are often designed with safety in mind, incorporating fail-safes and redundancy systems that can prevent catastrophic failures. This emphasis on safety not only protects the system itself but also safeguards personnel and the surrounding environment from potential hazards.

| Feature | Advantage |

|---|---|

| Energy Efficiency | Reduces operational costs and environmental impact. |

| Durability | Longevity decreases maintenance needs and cost. |

| Modular Design | Facilitates integration with existing systems. |

| Compliance | Adheres to international safety and performance standards. |

| Customization | Tailorable designs to fit specific operational needs. |

| Smart Technology Integration | Real-time monitoring and adjustments enhances operational efficiency. |

What makes Ksb Wk systems essential in industry?

Ksb Wk systems are crucial due to their efficiency, adaptability, and ability to manage challenging fluid operations, ensuring optimized industrial processes. Their cutting-edge engineering meets the demands of contemporary industries seeking to maintain competitive advantages.

Are Ksb Wk systems compatible with existing infrastructure?

Yes, their modular design ensures that they can be easily integrated with existing systems, making them a practical addition to various industrial environments. Companies can leverage their previous investments while effectively upgrading their systems’ capabilities.

How do Ksb Wk systems contribute to sustainability?

By maximizing energy efficiency and minimizing operational waste, Ksb Wk systems contribute significantly to sustainable industrial practices. Their ability to operate effectively under high-pressure conditions helps to lower energy consumption, thus reducing greenhouse gas emissions linked to production processes.

What maintenance is required for Ksb Wk systems?

Routine inspections and minor maintenance activities are generally sufficient due to their durable construction and advanced materials. Scheduled maintenance can include checking seals, bearings, and electronic interfaces to ensure peak performance. Additionally, utilizing predictive maintenance strategies can further enhance system life and performance.

The evolution of Ksb Wk systems is closely tied to advancements in technology and changes in market demands. Emerging trends such as the Internet of Things (IoT) and Industry 4.0 are set to enhance the functionality of these systems. The incorporation of IoT can lead to improved real-time data collection, which can be analyzed to optimize fluid handling processes further.

Moreover, artificial intelligence and machine learning algorithms can be integrated into Ksb Wk systems, allowing for predictive analytics that can foresee potential issues before they arise. This predictive capability ensures continuous operations while minimizing downtime, resulting in cost savings and improved operational effectiveness.

Additionally, enhancing the sustainability profile of Ksb Wk systems is becoming a key focus of manufacturers. Research and development into eco-friendly materials and processes are expected to become more prominent. There is also a growing emphasis on lifecycle assessments to ensure that all aspects of the system, from production through to disposal, minimize environmental impact. Innovations aimed at increasing efficiency and reducing energy consumption will lead to newer models that set higher standards for sustainability.

The economic impact of adopting Ksb Wk systems cannot be underestimated. By investing in these advanced systems, industries can significantly reduce their operational costs due to enhanced energy efficiency and decreased maintenance activities. The long-term savings often outweigh the initial capital expenditure involved in procuring and installing these systems.

Moreover, the improved reliability and reduced downtime contribute positively to a company's bottom line. Businesses can achieve higher productivity levels, meet production targets more consistently, and respond more swiftly to market demands. This agility is particularly vital in today’s fast-paced economic environment where responsive supply chains are essential.

Additionally, as industries increasingly focus on sustainability and corporate social responsibility, employing Ksb Wk systems supports a positive public image and can enhance customer relations. Being seen as an environmentally responsible entity can lead to increased sales and customer loyalty, ultimately contributing to the long-term success of a business.

To further illustrate the benefits and applications of Ksb Wk systems, let’s examine a case study in the chemical processing sector. A major chemical manufacturing facility was facing challenges with their traditional fluid handling systems, which often led to inefficiencies and frequent breakdowns. The company opted to transition to Ksb Wk systems, aiming for improved reliability and efficiency.

The initial implementation involved a thorough needs assessment, where engineers evaluated the existing systems and identified key areas for improvement. The Ksb Wk systems were tailored to meet specific operational demands, including handling hazardous materials and dealing with varying pressures and temperatures throughout production.

After deployment, the facility reported a significant reduction in maintenance costs, as the durability of the Ksb Wk systems meant fewer breakdowns and less frequent need for repairs. The enhanced energy efficiency resulted in a noticeable decrease in monthly energy expenses, all while maintaining or improving production output.

This case study exemplifies not only the operational improvements afforded by Ksb Wk systems but also the significant cost savings that can be realized through their use. Such tangible results make the case for investing in advanced fluid handling systems compelling, particularly as businesses seek to optimize their operations amid rising costs and environmental scrutiny.

The Ksb Wk systems represent a pinnacle of engineering excellence, offering unmatched performance, reliability, and efficiency. For industries seeking to modernize their fluid handling capabilities, these systems provide a future-proof solution, ensuring optimal productivity and environmental compatibility. By embracing the technological innovations embodied in Ksb Wk systems, companies can position themselves at the forefront of their industries while contributing to a sustainable future.

In summary, the ability of Ksb Wk systems to adapt to various industrial needs, support sustainability goals, and offer significant economic advantages makes them indispensable in today's fluid handling landscape. With further advancements on the horizon, the prospects for Ksb Wk systems continue to grow, ensuring that they will remain a critical component of effective industrial operations for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!